The RELO Products

The RELO Energy Efficient Grinding Bodies are a world innovation that radically changed the process of mill grinding. RELO Grinding Bodies are a new industrial design, patent-protected worldwide innovation, awarded with multiple international prizes and certificates.

~ ~ ~

Over the past 150 years the grinding of ore, cement, coal, construction materials, waste and others is carried out by grinding bodies mainly with spherical shape.

~ ~ ~

Back in 1864 in the USA began the milling of ores with spherical grinding bodies. Today this is an enormous industry - as they are a consumable without which the mining cannot work.

Download Presentations of RELO Energy Efficient Grinding Bodies and of their Inventor Dr. Eng. Petar Bodurov

|

|

| Presentation of the RELO Energy Efficient Grinding Bodies | Presentation of the Inventor - Dr. Eng. Petar Bodurov |

Over 30 million tons of grinding bodies are produced annually worldwide. And every year, their number and the need of efficiency will increase more and more. This ranks them among the most mass metal products, by volumes, in the world.

The form of the spheres is imposed in the world industry thanks to the study conducted in 1954 by English researcher Chad Norris, who ground different materials with different bodies - discs, cylinders, cones and others, using a laboratory mill. He determined that the spheres have the best performance in grinding. Everyone perceived them as granted and the research of alternative variations, which could increase the efficiency in the industry, stopped.

~ ~ ~

The ball is substantially the body with the smallest surface area, but with constant width. It is ideal - on all sides it is rounded, and therefore it rolls well. And this facilitates the processes of grinding and reduces the risks of damaging the inner coating of the mill.

However, when we examined what the drum mills - where the spheres are put – are, we understand that they represent cylinders in which there are free percussive elements that perform two main functions: first - to break, and then – to grind.

Due to their oval shape, the spheres are suitable for grinding, but they are too inefficient and it takes much more time and resources for them to perform the function of crushing.

Practice shows that in the mills are often put particles larger than the necessary and this significantly hampers the spheres. They just do not have the necessary ridgy shape to participate more effectively in the processes of crushing.

This led to the need to create the perfect body, which has oval sides suitable for grinding, and effective edges to crush the particles. Also, the form must not increase the risks of damaging the inner coating of the mills.

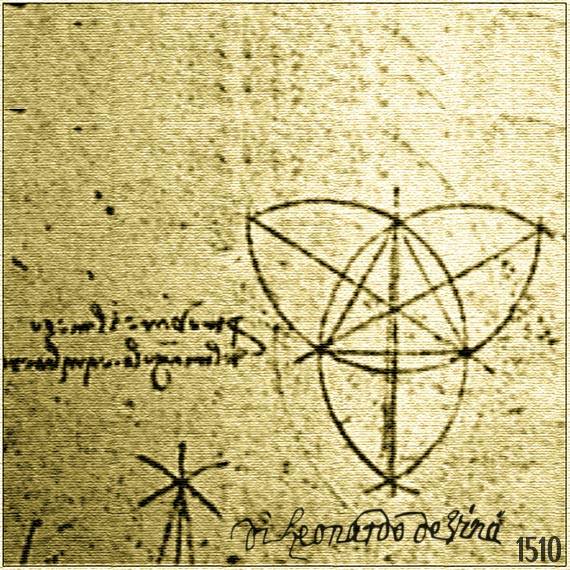

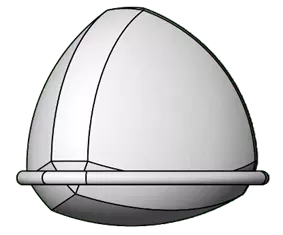

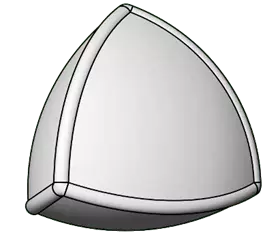

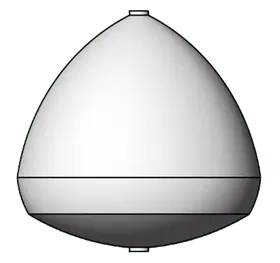

The shape of RELO Grinding Bodies (spheroidal tetrahedron) is based on geometric developments of the inventor Leonardo Da Vinci and the geometrician and mechanic Franz Reuleaux.

For the needs of the processing industry, this form has the perfect combination of 6/12 edges inclined at 120 degrees and four rounded vertices, which – no matter the angle at which they are falling – crush the coarse particles in the mill effectively and quickly. On the other hand, the spheroidal tetrahedron has with about 10% larger surface area compared to the same analogical sphere, and also a more sloping surface which leads to a larger area for grinding and larger contact surface. These factors improve by over 97% the produced quantity of ground material per hour, thus reducing in half the time for production and reducing with over 40% the electricity costs for each ton produced.

The form also has a lower center of gravity, which combined with the more sloping and larger sides of the tetrahedron, help the tetrahedrons to stand with the sloping side during the ascent, thus ascending higher that the rotating spheres. On the one hand, this leads to falling with greater kinetic energy on the particles and facilitates the processes of crushing and grinding, and on the other hand, reduces the risks of damaging the inner coating of the mills. These factors and the industrial and laboratory tests in the last seven years have proved indisputably that the new form has a number of advantages and qualities that demonstrate significant improvement and efficiency over the sphere for all indicators. And this is for both crushing and grinding, but also for the force of percussion when falling, for work endurance, efficiency, frugality, time.

In the process of research over the years were created a number of different models for the different needs and applications - for dry or wet grinding, for harder or softer materials - ore, cement, coal, rubber, porcelain and more.

~ ~ ~

The RELO Family holds over 300 patents in more than 65 countries and includes eight protected basic models of RELO Grinding Bodies, specialized in the processing of different types of materials:

| RELO Model М-1: | |

|

RELO Model М-1.1 – closely splayed edges.

Application: for monolithic materials with predominantly large crystals. RELO Model М-1.2 – widely splayed edges. |

| RELO Model М-2: | |

|

Production: only by forging.

Application: suitable for soft structures such as limestone, etc. |

| RELO Model М-3: | |

|

Application: for solid materials. |

| RELO Model М-4: | |

|

Application: for brittle materials and fine grinding. |

| RELO Model М-5: | |

|

Model sparing the lining. Application: grinding of porcelain, amber, etc. |

| RELO Model C-1: | |

|

Application: for dry grinding – cement, coal and others. |

| RELO Model C-2: | |

|

Production: only by forging.

Application: for dry grinding. |

RELO STANDARD

QUALITY REQUIREMENTS OF THE STEEL RELO GRINDING BODIES

FOR THE NEEDS OF THE DRUM MILLS

The present standard applies to the technological specification of rolled, casted and die forged steel grinding bodies of type RELO, used for grinding in the processing of ores, coal, clinker and other minerals, materials and waste.

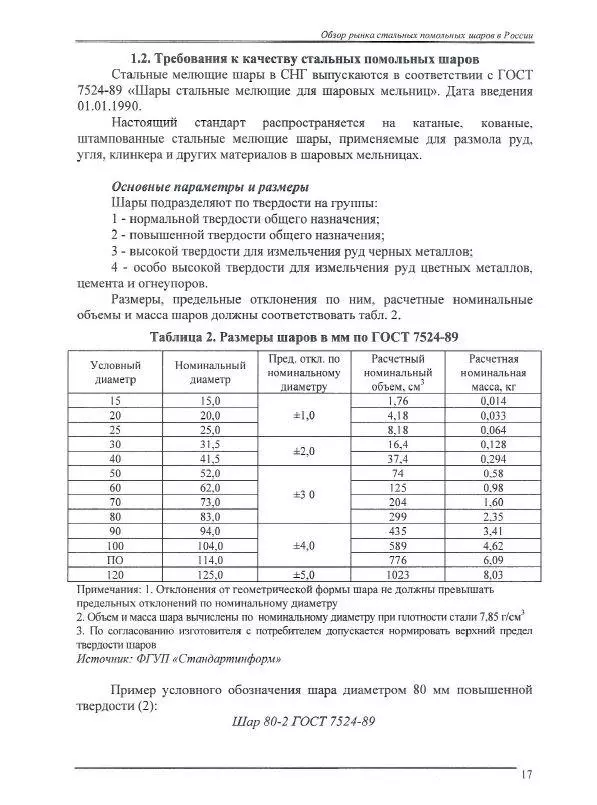

Comparative table between the specifications of spherical grinding bodies according to ГОСТ (GOST) and RELO Grinding Bodies

|

|

||||||

|

Standard for SPHERICAL BALLS |

Standard for RELO GRINDING BODIES |

||||||

|

N: |

MODEL |

NOMINAL D - F |

VOLUME ММ/3 |

N: |

MODEL |

HEIGHT ММ |

VOLUME ММ/3 |

|

1 |

Sphere |

15,00 |

1 766,25 |

1 |

Tetrahedron |

15,512 |

1 766,25 |

|

2 |

Sphere |

20,00 |

4 186,67 |

2 |

Tetrahedron |

20,683 |

4 186,67 |

|

3 |

Sphere |

25,00 |

8 177,08 |

3 |

Tetrahedron |

25,853 |

8 177,08 |

|

4 |

Sphere |

30,00 |

14 130,00 |

4 |

Tetrahedron |

31,024 |

14 130,00 |

|

5 |

Sphere |

40,00 |

33 493,33 |

5 |

Tetrahedron |

41,365 |

33 493,33 |

|

6 |

Sphere |

50,00 |

65 416,67 |

6 |

Tetrahedron |

51,706 |

65 416,67 |

|

7 |

Sphere |

60,00 |

113 040,00 |

7 |

Tetrahedron |

62,048 |

113 040,00 |

|

8 |

Sphere |

70,00 |

179 503,33 |

8 |

Tetrahedron |

72,389 |

179 503,33 |

|

9 |

Sphere |

80,00 |

267 946,67 |

9 |

Tetrahedron |

82,730 |

267 946,67 |

|

10 |

Sphere |

90,00 |

381 510,00 |

10 |

Tetrahedron |

93,071 |

381 510,00 |

|

11 |

Sphere |

100,00 |

523 333,33 |

11 |

Tetrahedron |

103,413 |

523 333,33 |

|

12 |

Sphere |

110,00 |

696 556,67 |

12 |

Tetrahedron |

113,754 |

696 556,67 |

|

13 |

Sphere |

120,00 |

904 320,00 |

13 |

Tetrahedron |

124,095 |

904 320,00 |

|

14 |

Sphere |

130,00 |

1149 763,33 |

14 |

Tetrahedron |

134,436 |

1 149 763,33 |

|

15 |

Sphere |

140,00 |

1 436 026,67 |

15 |

Tetrahedron |

144,778 |

1 436 026,67 |

|

16 |

Sphere |

150,00 |

1 766 250,00 |

16 |

Tetrahedron |

155,119 |

1 766 250,00 |

|

17 |

Sphere |

160,00 |

2 143 573,33 |

17 |

Tetrahedron |

165,460 |

2143 573,33 |

Basic parameters and dimensions

Distribution of the hardness of RELO Grinding Bodies by groups

1 - Grinding bodies with normal hardness - HRC 52 – 56

2 - Grinding bodies with increased hardness - HRC 56 – 58

3 - Grinding bodies with high hardness - HRC 58 – 60

4 - Grinding bodies with particularly high hardness - HRC 60 – 62

Standard for RELO Grinding Bodies

|

№ |

MODEL / SIZE |

HEIGHT MM |

VOLUME CМ/3 |

CALCULATED WEIGHT KG |

% ACCEPTABLE TOLERANCES IN THE VOLUME |

|

1 |

R15 |

15,512 |

1,8 |

0,014 |

+1.0 |

|

2 |

R20 |

20,683 |

4,2 |

0,033 |

+1.0 |

|

3 |

R25 |

25,853 |

8,2 |

0,064 |

+1.0 |

|

4 |

R30 |

31,024 |

14,1 |

0,111 |

+2.0 |

|

5 |

R40 |

41,365 |

33,5 |

0,263 |

+2.0 |

|

6 |

R50 |

51,706 |

65,4 |

0,513 |

+3.0 |

|

7 |

R60 |

62,048 |

113.0 |

0,887 |

+3.0 |

|

8 |

R70 |

72,389 |

179,5 |

1,410 |

+3.0 |

|

9 |

R80 |

82,730 |

267,9 |

2,103 |

+3.0 |

|

10 |

R90 |

93,071 |

381,5 |

2,995 |

+4.0 |

|

11 |

R100 |

103,413 |

523,3 |

4,108 |

+4.0 |

|

12 |

R110 |

113,754 |

696,6 |

5,468 |

+4.0 |

|

13 |

R120 |

124,095 |

904,3 |

7,099 |

+4.0 |

|

14 |

R130 |

134,436 |

1149,8 |

9,026 |

+5.0 |

|

15 |

R140 |

144,778 |

1436,0 |

11,273 |

+5.0 |

|

16 |

R150 |

155,119 |

1766,3 |

13,865 |

+5.0 |

|

17 |

R160 |

165,460 |

2143,6 |

16,827 |

+5.0 |

Notes:

1. The volume of the grinding bodies type RELO is calculated for relative weight of the steel being 7,85 g/ cm/3.

2. For the different materials and conditions of grinding are offered the following models of RELO Grinding Bodies:

2.1 Grinding bodies for dry grinding: С-1, С-2.

2.2 Grinding bodies for wet grinding: M-1 (M-1.1, M-1.2, M-1.3), M-2, M-3, M-4, M-5.

Example:

Conditional designation of grinding body with size 80, model M-1.1, hardness 3

- Grinding body R 80 – M-1.1 /3

Download the RELO Standard and the GOST Standard

|

|

| RELO Standard | GOST Standard |